Painting Process In Automotive Industry Ppt8 As the shell exits the cleaning station it goes via a drying booth and then via an undercoat dip—an electrostatically charged bath of undercoat paint (referred to as the E-coat) that covers each nook and cranny of the physique shell, each inside and out, with primer. This coat acts as a substrate surface to which the best coat of colored paint adheres.

One element and two portion formulations are usually referred to as 1k and 2k respectively. 7 OEM (original equipment manufacture) clear coats applied to the metal bodies of cars are typically 1K systems since they can be heated to about 140 deg C to effect cure. The clear coats applied to the plastic components like the bumpers and wing mirrors nonetheless are 2K systems considering that they can usually only accept temperatures up to about 90 deg C. These 2 K systems are usually applied “off line” with the coated plastic components fixed to the painted metallic body. Owing to the distinction in formulation of the 1K and 2K systems and the fact they are coated in various locations they have a different effect on the “redissolving” of the metallic base coat. This is most very easily observed in the light metallic paints like the silver and light blue or green shades exactly where the “flop” distinction is most marked.

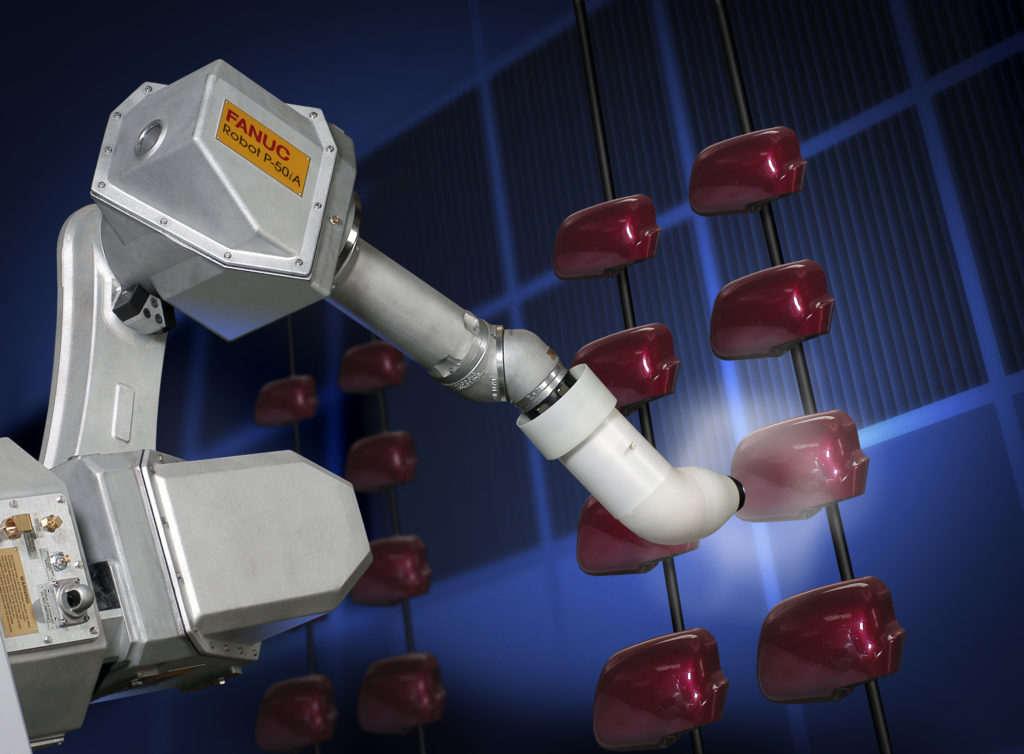

9 Soon after the E-coat bath, the shell is once again dried in a booth as it proceeds on to the final paint operation. In most automobile assembly plants nowadays, car bodies are spray-painted by robots that have been programmed to apply the precise amounts of paint to just the proper places for just the right length of time. Considerable investigation and programming has gone into the dynamics of robotic painting in order to ensure the fine “wet” finishes we have come to expect. Our robotic painters have come a extended way because Ford’s initial Model Ts, which were painted by hand with a brush.

Phosphate Industry PptPainting Process In Automotive Industry Ppt

Painting Process In Automotive Industry PptAlthough the bulk of an automobile is virgin steel, petroleum-based items (plastics and vinyls) have come to represent an increasingly massive percentage of automotive components. The light-weight materials derived from petroleum have helped to lighten some models by as much as thirty %. As the value of fossil fuels continues to rise, the preference for lighter, much more fuel efficient vehicles will become more pronounced.

The significant alter that has taken location in the coatings market in the course of the last 40 years has been the adoption of new coating technologies. These new coating technologies consist of waterborne (thermosetting emulsion, colloidal dispersion, water-soluble) coatings, higher-solids coatings, two-component systems, powder coatings, and radiation-curable coatings.

High price: The high-cost of Teflon-coating application is one more down side. Car dealers often charge higher amounts in excess of ₹3,000 to coat a vehicle, exactly where most of the price goes towards the dealer’s profit margin. If you have the time and patience, a great difficult wax is a better choice for your vehicle. Conic Automotive Pvt. Ltd.

ACMA Automotive Element Makers Association Of Indiapainting process in automotive industry ppt

painting process in automotive industry pptIn 1908 Henry Ford began production of the Model T automobile. Primarily based on his original Model A design very first manufactured in 1903, the Model T took 5 years to create. Its creation inaugurated what we know today as the mass production assembly line. This revolutionary idea was primarily based on the idea of just assembling interchangeable element components. Prior to this time, coaches and buggies had been hand-built in little numbers by specialized craftspeople who hardly ever duplicated any specific unit. Ford’s revolutionary style lowered the number of components needed as nicely as the quantity of skilled fitters who had constantly formed the bulk of the assembly operation, giving Ford a tremendous advantage over his competition.

7 Prior to painting, the body need to pass by way of a rigorous inspection method, the physique in white operation. The shell of the car passes by way of a brightly lit white room where it is completely wiped down by visual inspectors utilizing cloths soaked in hi-light oil. Beneath the lights, this oil permits inspectors to see any defects in the sheet metal physique panels. Dings, dents, and any other defects are repaired appropriate on the line by skilled physique repairmen. Soon after the shell has been totally inspected and repaired, the assembly conveyor carries it through a cleaning station exactly where it is immersed and cleaned of all residual oil, dirt, and contaminants.

A single new region of interest is nanotechnology, with tens of thousands of patents issued already just for the coatings market. Very tiny ceramic or metallic particles can be added to paint formulations to modify distinct properties (e.g., scratch, mar, put on, corrosion, and UV resistance) in very specialized applications. The average size of nanoparticles is 10-70 nanometers, consisting of less than six.five million atoms. At these sizes, the ratio of surface location to mass becomes considerable, giving the particles special properties. For instance, at two nanometers, the conductivity of metal particles changes and at 20 nanometers, the transparency of ceramic particles alterations. At 20 nanometers, particles of gold turn red and their plasticity disappears.

Automotive Painting Processespainting process in automotive industry ppt

Painting Process In Automotive Industry Ppt13 The chassis assembly conveyor and the body shell conveyor meet at this stage of production. As the chassis passes the physique conveyor the shell is robotically lifted from its conveyor fixtures and placed onto the automobile frame. Assembly workers, some at ground level and some in perform pits beneath the conveyor, bolt the vehicle physique to the frame. Once the mating takes spot the automobile proceeds down the line to get final trim components, battery, tires, anti-freeze, and gasoline.

2 The typical vehicle or truck is constructed from the ground up (and out). The frame types the base on which the body rests and from which all subsequent assembly components comply with. The frame is placed on the assembly line and clamped to the conveyer to prevent shifting as it moves down the line. From right here the automobile frame moves to component assembly locations where full front and rear suspensions, gas tanks, rear axles and drive shafts, gear boxes, steering box elements, wheel drums, and braking systems are sequentially installed.

12 Next, robots equipped with suction cups remove the windshield from a shipping container, apply a bead of urethane sealer to the perimeter of the glass, and then location it into the physique windshield frame. Robots also choose seats and trim panels and transport them to the automobile for the ease and efficiency of the assembly operator. Right after passing via this section the shell is offered a water test to make certain the suitable fit of door panels, glass, and weatherstripping. It is now ready to mate with the chassis.