Product design and development in automobile industrySmithers delivers a wide range of product improvement, quality management and info solutions for the automotive market. KPO is Understanding Processing Outsourcing, not to be confused with BPO, which is Company Processing Outsourcing. KPO is about supplying understanding primarily based services in the regions like market place research, business analysis, economic analysis, legal services, and so on., whilst BPO is about providing client care solutions, technical assistance, tele-sales and so on. KPO industry is anticipated to grow from US $ 1.3 billion in the year 2003 to US $ 17 billion in the year 2010. KPO sector is anticipated to develop at a compounded annual growth price (CAGR) of 49.5% till 2010. According to the National Association of Software and Services Businesses (NASSCOM), But according to Rocsearch, a UK based research firm, KPO sector will be able to reach 100,000 employees only instead of 250,000 workers. As a result, to fill the demand and supply gap coaching has now turn into an crucial tool like every single other technical sector.

The Automotive Innovation and Product Improvement Center will serve as Intel’s global center of competence for the development of products and technologies for in-automobile infotainment and telematics solutions for the connected vehicle. The center will optimize Intel technologies for applications and solutions as properly as capabilities for customer electronics integration, efficiency optimization and program style.

Aptina has published a whitepaper on Clarity+ technologies Clarity+ starts with the normal 2×2 Bayer RGB colour filter pattern typically utilized in image sensors all through the market, and then replaces all of the green color filters with meticulously optimized clear filters. This pattern preserves the high-frequency spatial details of the Bayer pattern, eliminating the aliasing artifacts that are inevitably introduced when both green and clear filters are utilised in bigger kernel (4×4) patterns. The green colour is determined by way of the image processing algorithms that use subtractive and interpolation techniques. Specialized noise reduction is then applied, resulting in a 3dB improvement in low-light SNR, relative to that feasible with the RGB Bayer pattern.

Solution & Engineering Services For Automotiveproduct design and development in automobile industry

new product development in automotive industry pptProgram controls is in automotive product design and style and improvement. Even though most automotive solution improvement cycles have been shortening for organizations of all sizes, it also seems that they are having troubles keeping up with the modifications. Regardless, there are challenges all businesses face in compressing their solution improvement cycles with testing, supply chain and manufacturing taking the top 3 spots.

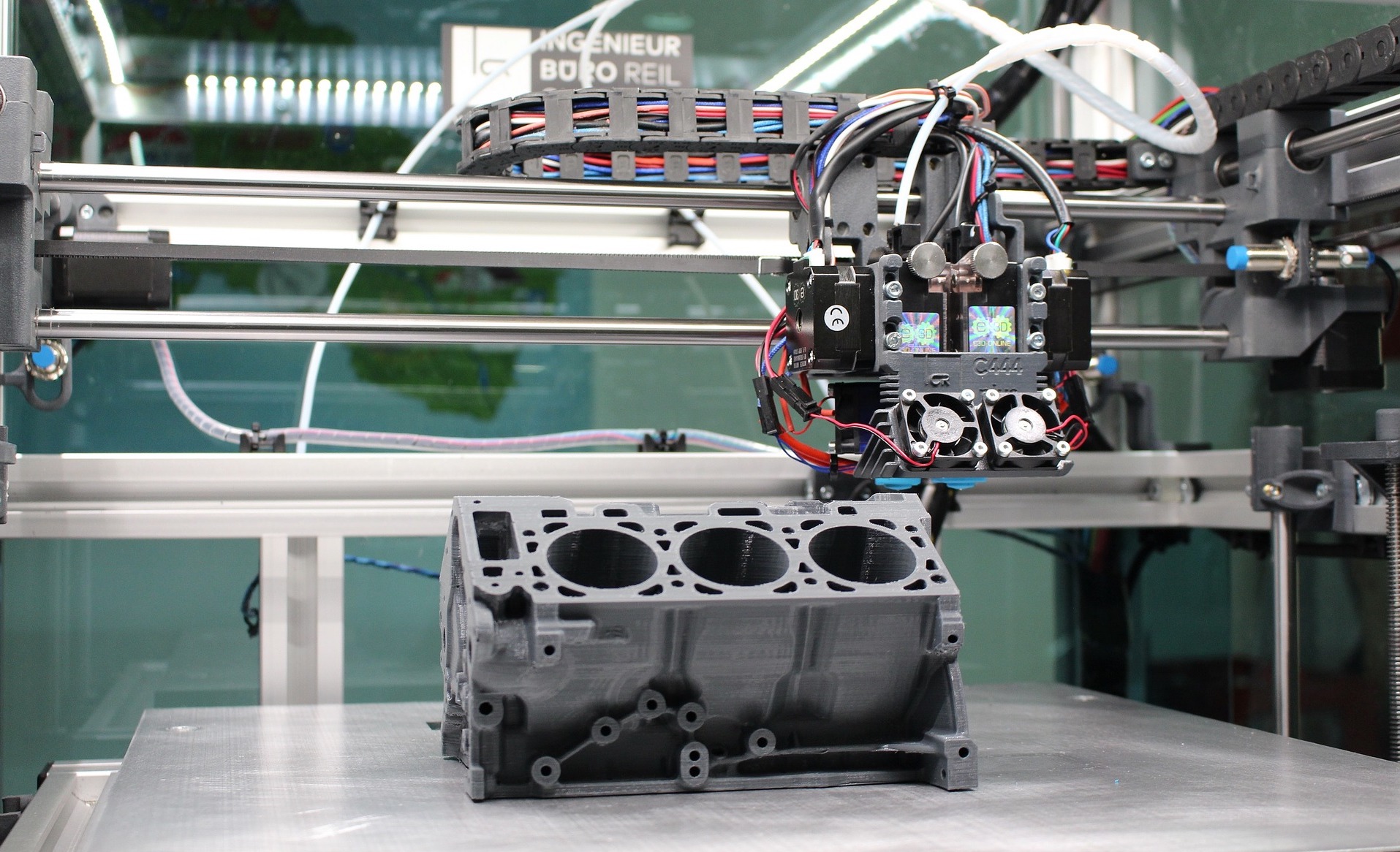

Style and improvement tools are altering as well. Businesses can create and test detailed virtual models of their designs, permitting them to evaluate several design options and recognize and resolve issues ahead of any prototype hardware is manufactured. In the automotive business, the use of such virtual prototyping techniques has helped to cut the time essential to develop a new vehicle from 36 months to 24 months given that the 1990s. Artificial intelligence techniques are helping designers and engineers locate far better solutions to difficult trade-offs and optimization difficulties. Airbus used a method that mimics bone growth in animals to develop a 3D-printed wall for aircraft cabins that weighs 55 % much less than the standard design.

Digital technologies also enable organizations to offer you new services alongside their goods. Sensors constructed into cars or manufacturing gear can spot inform-tale evidence of mechanical difficulties, permitting predictive upkeep interventions. Black-box information recorders in automobiles let insurance coverage firms adjust their rates according to the way the automobile is driven.

Cycle Item Improvement Procedure In The Automotive Industry?product development with sap in the automotive industry

product development in automobile industrySmithers gives a wide range of product improvement, top quality management and details services for the automotive market. Model the application: Given the importance of application in automotive, it really is crucial to make it much less difficult to develop, document, shop and run tests on codes. An integrated application environment makes it less complicated to create and handle embedded software from project inception to end-of-life and make this procedure integral to the general vehicle improvement program. This enables management of large-scale software deployments whilst ensuring traceability and error checking.

1 factor you have to understand is, a huge chunk of the workers within an automotive company have been in the sector longer than most new-graduate-hires have been alive. It really is an indication of how lengthy the processes have been calcified in place, and it ought to give you an notion of how difficult it is to implement and inspire new development frameworks.

The Denso Corporation, a longtime member of Toyota’s supplier keiretsu and now a worldwide player in the automotive business, offers a excellent example of how an invisible subassembly supplier ought to be integrated in new item improvement. Denso styles a family of alternators to help the Toyota vehicle item line. Toyota keeps Denso informed of the overall solution line method, but then expects Denso to create a range of components that can meet the wants defined by the critical systems, at a previously agreed-upon cost target. Denso usually produces an evolving lineup of five or six different-sized alternators to help the dozens of models and hundreds of energy-train configurations provided in Toyota’s vehicles.

CAE Driven Design For Security, Comfort And Good quality For The Automotive Businessproduct development process in automotive industry

project management on new product development and launch in the automotive industryEstablishing new revolutionary merchandise in the automotive sector indicates investing enormous sums in advance, as one particular does not know if the item will be productive on the market after launch. In the U.S. the needle punching sector of the nonwovens sector has usually been the black sheep of the nonwovens industry. Needle punching nevertheless has the connotation of getting a slow, non-technical technology. Internationally, nonetheless, it is fascinating to note that these adverse connotations relating to needle punching are not so prevalent. This is specially correct in Asian markets. The easy fact of the matter is that many U.S., businesses do not completely recognize the needle punching method nor the emerging and establishing markets. In addition, organizations cannot see a lucrative future in needle punching.

The enterprise challenge: The client is an American multinational automotive corporation headquartered in Detroit, Michigan. Offered the multitude of new goods accessible in the market place, the client faced extreme difficulty in setting themselves apart from the international competition. Additionally, the client was facing predicaments in analyzing the client requirements and adoption of technologies, due to which they have been lagging compared with their peers. Thus, with Infiniti’s product research engagement, the client wanted to analyze the segments that their product is geared towards and predict future getting habits of buyers. Additionally, the client wanted to lessen solution development charges by making use of reduce-price materials and by redesigning the solution according to the customers’ requirement.

Intel also announced plans for a complete academic system that includes fundamental and applied analysis, curriculum improvement and internship applications to foster the exchange of innovative concepts amongst academia, Intel and the automotive industry. The plan will be hosted at the Karlsruhe website and will tap into an extensive Intel European Research and Development network of researchers and developers, labs and research relationships.